– Michelin is opening a new automated mask manufacturing workshop at the Combaude plant near Clermont-Ferrand

– An investment of €3.5 million and output of 4 million units per month to meet the needs of businesses and society

– A partnership between Michelin and French company CERA to process engineer mask manufacturing machines in France.

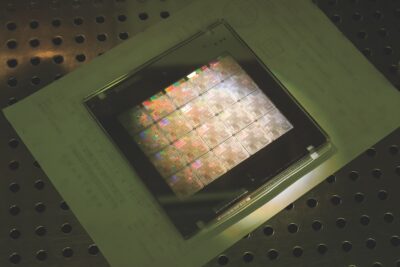

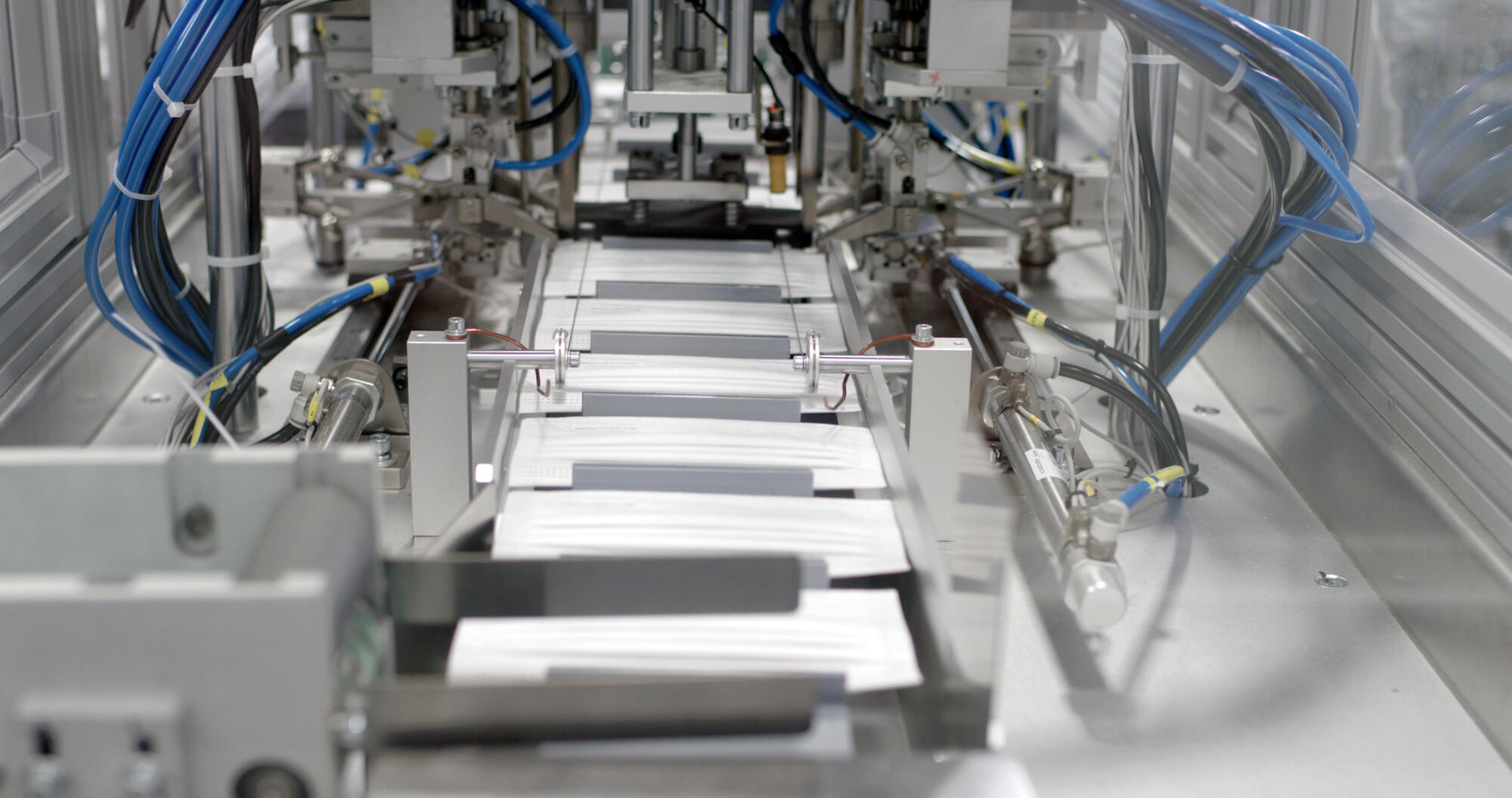

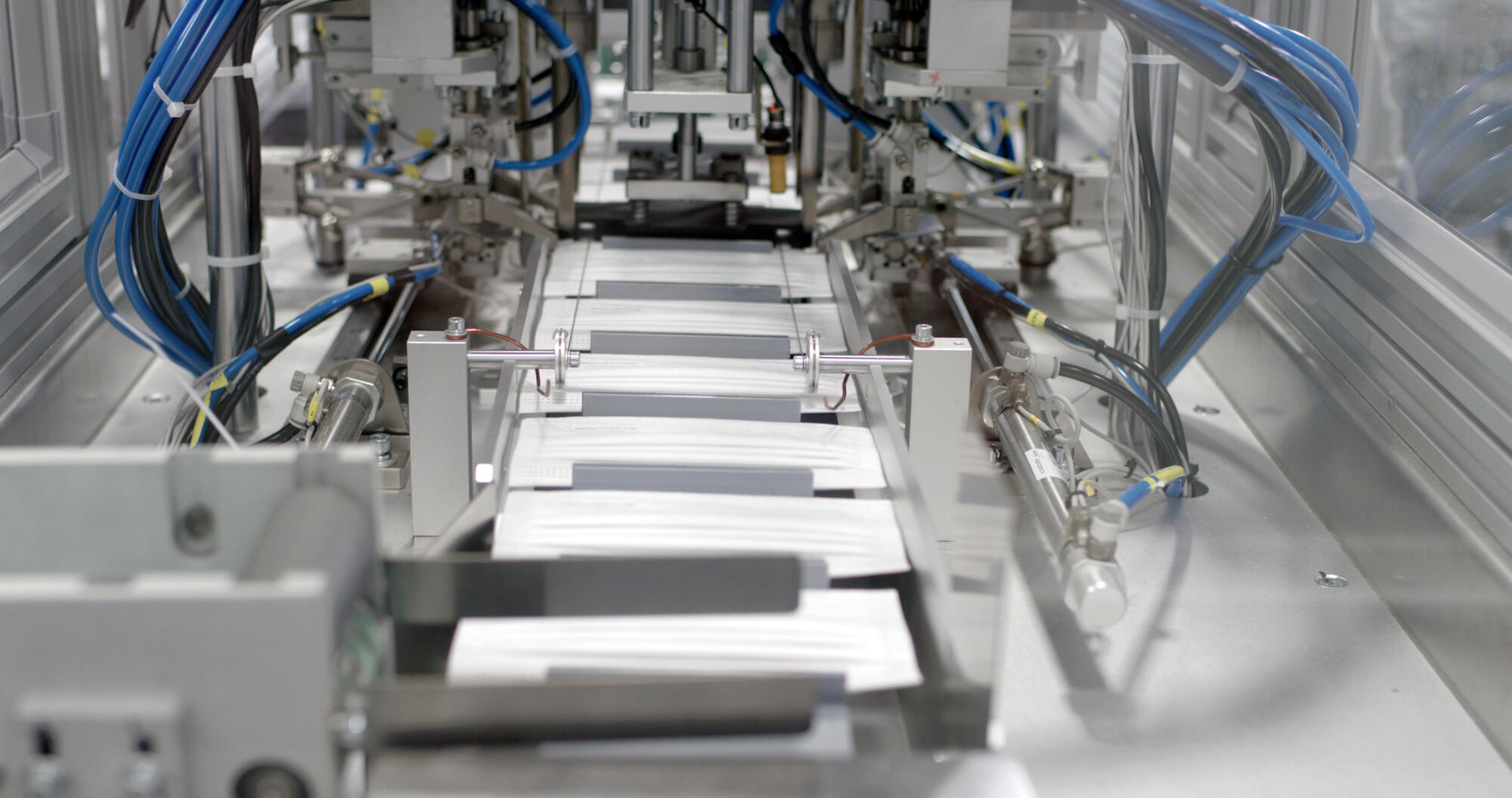

Michelin is stepping up its commitment to mask production. The Group has just launched its first automated mask production workshop in France, at its Combaude plant near Clermont-Ferrand. The €3.5 million investment allows for the production of 3 million standard type I or IIR single-use surgical masks per month. Production will ramp up to include 1 million FFP2* masks per month from summer 2021.

The new facility is designed to address the need to protect Michelin’s 68,000 employees in Europe. Any surplus will be sold in order to contribute to the fight against epidemics.

The workshop is equipped with a level 9 room on the classification scale for air cleanliness by particle concentration (ISO Standard 14644-1)**. During the development and certification phases, in order to meet France’s EN 14683 2019 standard for surgical masks, Michelin called on the assistance of a certified laboratory based in Spain, a French laboratory affiliated with INSERM, the Icare laboratory for biocompatibility and the Clermont-Ferrand University Hospital.

A partnership between Michelin and CERA to step up the process engineering of machines

Some of the machines used in the new workshop come from the French company CERA. In response to the government’s call for the relocation of medical equipment production to France, CERA, based in Villars in the Auvergne-Rhône-Alpes region, asked Michelin for its support, via its subsidiary Imeca. The aim of this collaborative endeavor is to use Michelin’s engineering know-how to help rapidly increase production capacity for new machines. Thanks to this partnership and to five other assemblers who have joined the project, CERA’s annual production has increased from two to 52 machines.

* APAVE certification of the FFP2 mask in progress

** The level 9 standard implies not exceeding 70% humidity in the production and storage environment.

Michelin, the leading mobility company, is dedicated to enhancing its clients’ mobility, sustainably; designing and distributing the most suitable tires, services and solutions for its clients’ needs; providing digital services, maps and guides to help enrich trips and travels and make them unique experiences; and developing high-technology materials that serve a variety of industries.

Headquartered in Clermont-Ferrand, France, Michelin is present in 170 countries, has 123,600 employees and operates 71 tire production facilities which together produced around 170 million tires in 2020. (www.michelin.com).

- Michelin is opening a new automated mask manufacturing workshop at the Combaude plant near Clermont-Ferrand

- An investment of €3.5 million and output of 4 million units per month to meet the needs of businesses and society

- A partnership between Michelin and French company CERA to process engineer mask manufacturing machines in France.

Michelin is stepping up its commitment to mask production. The Group has just launched its first automated mask production workshop in France, at its Combaude plant near Clermont-Ferrand. The €3.5 million investment allows for the production of 3 million standard type I or IIR single-use surgical masks per month. Production will ramp up to include 1 million FFP2* masks per month from summer 2021.

The new facility is designed to address the need to protect Michelin's 68,000 employees in Europe. Any surplus will be sold in order to contribute to the fight against epidemics.

The workshop is equipped with a level 9 room on the classification scale for air cleanliness by particle concentration (ISO Standard 14644-1)**. During the development and certification phases, in order to meet France's EN 14683 2019 standard for surgical masks, Michelin called on the assistance of a certified laboratory based in Spain, a French laboratory affiliated with INSERM, the Icare laboratory for biocompatibility and the Clermont-Ferrand University Hospital.

A partnership between Michelin and CERA to step up the process engineering of machines

Some of the machines used in the new workshop come from the French company CERA. In response to the government's call for the relocation of medical equipment production to France, CERA, based in Villars in the Auvergne-Rhône-Alpes region, asked Michelin for its support, via its subsidiary Imeca. The aim of this collaborative endeavor is to use Michelin's engineering know-how to help rapidly increase production capacity for new machines. Thanks to this partnership and to five other assemblers who have joined the project, CERA's annual production has increased from two to 52 machines.

* APAVE certification of the FFP2 mask in progress

** The level 9 standard implies not exceeding 70% humidity in the production and storage environment.

Michelin, the leading mobility company, is dedicated to enhancing its clients’ mobility, sustainably; designing and distributing the most suitable tires, services and solutions for its clients’ needs; providing digital services, maps and guides to help enrich trips and travels and make them unique experiences; and developing high-technology materials that serve a variety of industries.

Headquartered in Clermont-Ferrand, France, Michelin is present in 170 countries, has 123,600 employees and operates 71 tire production facilities which together produced around 170 million tires in 2020. (www.michelin.com).